According to your company's requirements, the following are the configuration requirements for the VZU1600N fully automatic desulfurization gypsum dewatering centrifuge produced by our company, including picture display, technical parameters, structural principles, workflow, and electrical related technical documents. The following explanations are provided for reference only:

1、 Physical picture of Hengrui Pharmaceutical Machinery model:

2、 Technical parameters and structural principles of centrifuge:

1. Main technical parameters of centrifuge:

1.1 Equipment Name: Flat Plate (Reinforced) Fully Automatic Scraper Bottom Discharge Centrifuge

1.2 Equipment model: VZU1600N

1.3 Drum diameter: 1600mm

1.4 Drum height: 1250mm

1.5 Effective volume: 1300L

1.6 Drum speed: 0-820 r/min

1.7 Drum thickness: 22+mm

1.8 Maximum separation factor: 573

1.9 Loading limit: 2200kg

1.10 Production: 130T/D

1.10 Main motor power: 160kw (ABB variable frequency motor)

1.11 Main frequency converter power: 185kw

1.12 Weight: Approximately 13000 kg

1.13 Dimensions: 3100 × 2540 × 2680mm

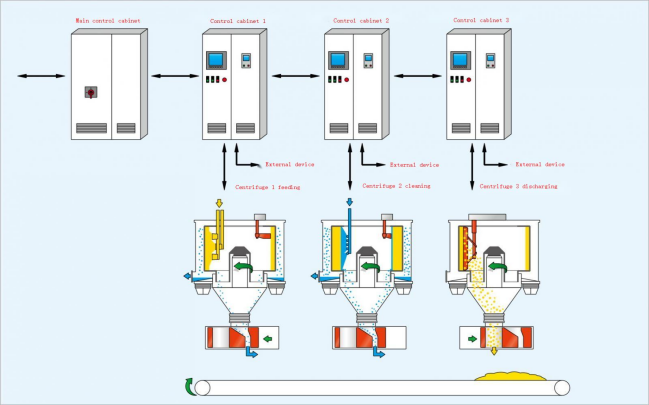

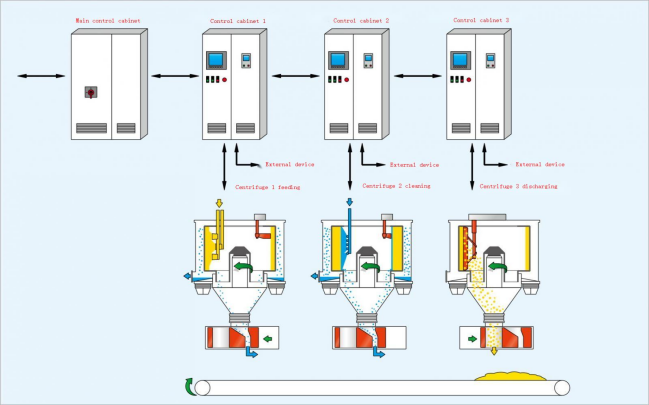

2、 Centrifuge working process

3、 Summary of Technical Parameters for Centrifuges:

| 项目名称entry name | 厂家设计数据Manufacturer design data | 备 注remarks |

| 离心机型号Centrifuge model | VZU1600N |

|

| 进料方式feeding method | 双进料管侧进料Double feeding tube side feeding |

|

| 出料方式Discharge method | 刮刀下卸料Scraper unloading |

|

| 离心机支撑方式Centrifugal support method | 四点支撑Four point support |

|

| 减振系统damping system | 高粘度液态阻尼减振器High viscosity liquid damping shock absorber |

|

| 主机驱动方式Host driver mode | 变频器启动Inverter startup |

|

| 制动方式Braking method | 能耗制动dynamic braking |

|

| 主机控制方式Host control mode | PLC 程序控制PLC program control |

|

| 离心机主要设计参数Main design parameters of centrifuge |

转鼓内径(mm)

Inner diameter of drum | 1600 |

|

转鼓高度(mm)

Drum height | 1250 |

|

拦液板厚度(mm)

Thickness of liquid blocking plate | 20 |

|

| 转鼓厚度(mm)Drum thickness | 22+ |

|

盖板厚度(mm)

Thickness of cover plate | 30(包衬2mm不锈钢316L)

30 (lined with 2mm stainless steel 316L) |

|

外壳法兰厚度(mm)

Thickness of shell flange | 30 |

|

平板厚度(mm)

slab thickness | 100灌胶高度220mm 100 glue filling height 220mm |

|

拦液口直径(mm)

Diameter of liquid interception port | 1150 |

|

转鼓容积(L)

Drum capacity | 1300 |

|

最大装料限量(Kg)

Maximum loading limit | 2200 |

|

| 转速(rpm)speed | 820 |

|

| 最大分离因数(G)Maximum separation factor | 602 |

|

| 整机重量(Kg)Maximum separation factor | 13000 |

|

| 外形尺寸(LxWxH)(mm)External dimensions | 3100×2540×2680 |

|

| 转鼓旋转方向Rotation direction of drum | 顺时针(俯视机器)Clockwise (looking down at the machine) |

|

主电机功率kw

Main motor power | 160 | ABB变频电机 |

液压站电机功率kw

Hydraulic station motor power | 1.5 |

|

噪声水平(离机1米处)

Noise level (1 meter away from the aircraft) | ≤85dBA |

|

| 残余滤饼厚度Residual filter cake thickness | 约8mm |

|

| 料位探测方式Material level detection method | Mechanical level detector |

|

| 外部检测方式External detection method | 通过视镜孔Through the mirror hole |

|

| 离心机使用条件Centrifugal machine usage conditions |

环境温度°C

Environmental temperature ° C | -10~45空气相对湿度不大于85%

10-45. The relative humidity of the air should not exceed 85% |

|

| 设计温度°C Design temperature ° C | -10~80 |

|

| 设计压力(mbar)Design pressure | 80 |

|

| 空气源压力Air source pressure | 5-7bar |

|

| 洗涤液压力Washing liquid pressure | ≥2bar |

|

| 主电源main power supply | 3相5线制/50HZ/380V

3-phase 5-wire system/50HZ/380V |

|

| 联接管口及机盖孔设置Setting of connecting pipe openings and machine cover holes |

| 加料管feed pipe | DN80(标准法兰)Standard flange |

|

| 洗涤管Washing tube | DN50(标准法兰)Standard flange |

|

| 充氮管Nitrogen filling tube | DH10气接头Gas connector |

|

| 出液管Liquid outlet pipe | DN200法兰连接Flange connection |

|

| 灯镜Lamp mirror | φ130x10 |

|

| 视镜Mirror | φ180x10 |

|

| 设计制造标准Design and Manufacturing Standards | 符合JB/T10769.2-2007 |

|

| 离心拦板设计Centrifugal barrier design | 符合GB/T28695-2012 |

|

| 离心机振动检测Centrifugal vibration detection | 符合GB/T10895-2004 |

|

| 轴承润滑bearing lubricatio | 2#极压复合锂基脂2 # Extreme pressure composite lithium grease |

|

| 主要部分材质Main material components |

| 与物料接触部分材质Material of the part in contact with the material | 不锈钢316L材质Stainless steel 316L material |

|

| 离心机机座 Centrifuge machine base | 机座表面及侧面包衬304不锈钢,反面喷漆The surface and side of the machine base are lined with 304 stainless steel, and the back is painted with paint |

|

| 顶盖top cap | 不锈钢316L材质(包衬)Stainless steel 316L material (lined) |

|

| 机壳Shell | 不锈钢316L材质Stainless steel 316L material |

|

| 加料/洗涤/出液等外接管件External fittings for feeding, washing, and discharging | 不锈钢316L材质Stainless steel 316L material |

|

| 主轴main shaft | 42CrMo 锻打件42CrMo forged parts |

|

| 转鼓drum | 转鼓筒体及拦液板采用不锈钢316L材质

The drum body and liquid blocking plate are made of stainless steel 316L material |

|

转鼓底采用浇钢件包衬不锈钢316L材质

The bottom of the drum is made of cast steel parts lined with stainless steel 316L material |

| 横向刮刀、刮刀表面 | 横向刮刀不锈钢316L材质,刮刀外箱体材质为碳钢喷漆 |

|

| 出料斗 | 不锈钢316L材质 |

|

| 减振器 | 碳钢喷漆 |

|

| 密封件 | 硅胶或氟胶 |

|

| 主控制柜 |

| 放置区域 | 控制室 |

|

| 防护等级 | IP44 |

|

| 电缆通道 : | 下进下出 |

|

| 面板设置 | 急停按钮、触摸屏(非防爆) |

|

| 材质 | 碳钢喷塑 |

|

| 变频器品牌 | ABB | S120 smart series |

| 电源模块: PNDC=250kW |

| 电机模块: PN=160kW |

| PLC 品牌 | SIENEMS | SIMAICS(S7-1200) |

| 触摸屏 | SIEMENS | SIMAICS(12英寸) |

| 低压电器 | 中国德力西控股集团 |

|

| 现场防爆按钮 |

| 放置区域 | 现场 |

|

| 面板设置 | 各段速按钮、状态指示灯、急停按钮等 |

|

| 材质 | 碳钢喷塑 |

|

| 厂家 | 张家港市恒瑞制药机械有限公司 |

|

| 外形尺寸(高宽厚)mm | 500x330x160 |

|

| 液压系统 |

| 油泵电机功率 | YBX3 90L-4-B5(1.5kw) |

|

| 相位/频率/电压 | 3/50/380 |

|

| 电机及阀门防爆等级 | EX.dⅡBT4 |

|

| 系统最高压力 | 10Mpa |

|

| 液压系统的配置 | 电机、油泵、压力计、过滤器、电磁阀等 |

|

|

|

|

4、 The centrifuge randomly provides a list of technical documents:

1. Centrifuge user manual;

2. User manual for frequency converter;

3. Electrical wiring diagram;

4. Equipment quality inspection report;

5. Centrifuge delivery list.

5、 Centrifuge supply list:

1. Centrifuge host (including explosion-proof motor);

2. Main electrical control cabinet;

3. Hydraulic station system;

4. DN65 hydraulic or pneumatic ball valve

5. Imported filter screen;

6. Explosion proof control box;

7. Aggregate hopper.