PRODUCT CENTER

|

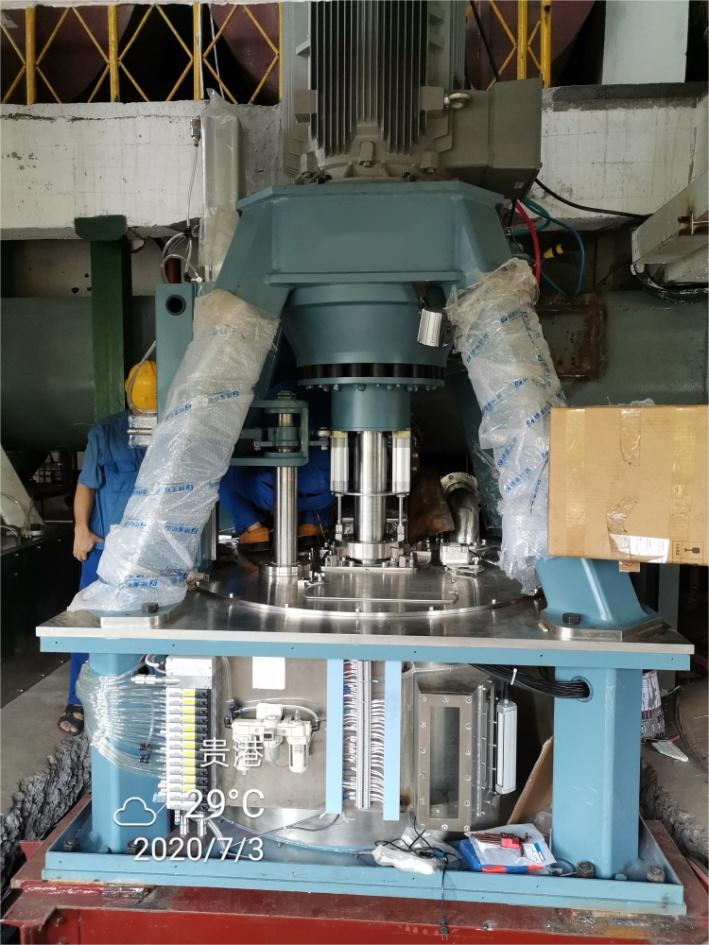

XJZ hanging centrifuge

收藏

brief introduction XGZ centrifuge is a fully automatic centrifuge with a suspended mechanical scraper for unloading. It separates sugar and honey under the action of centrifugal force field, and completes the unloading process by scraping the sugar material off the drum wall through the radial and axial movement of the scraper. The machine is equipped with water washing and steam washing devices, which thoroughly wash the materials. scope of application 1. The machine is equipped with water washing and steam washing devices, which fully wash the materials and meet the requirements of sugar production process. 2. This machine is widely used for separating glucose paste and is a key equipment in the glucose industry. 3. This machine can also be used to separate materials with fine solid grains, high viscosity, good flowability, compact texture, and difficult to discharge by gravity. Generally, a solid-liquid ratio (weight ratio) of 40-60% is suitable for suspensions. 4. This machine has good performance and the following characteristics: ⑴ Adopting AC variable frequency drive, in the automatic cycle operation of the cycle, variable frequency stepless speed regulation can greatly meet the requirements of low-speed feeding, high-speed separation, low-speed unloading and other speed requirements. According to the changes in material properties, corresponding speed points can be provided to achieve more optimized operations. ⑵ The electrical control adopts programmable logic controller (PLC). The 10 inch color touch screen can set the time for each process and display the real-time working status of each process, with flexible, simple, and convenient operation. The whole machine is controlled by a combination of electrical, pneumatic, and mechanical components, achieving fully automatic cyclic operation of each process. The parts in contact with the material are made of austenitic stainless steel to ensure cleanliness and hygiene of sugar and paste. The overall structure is compact and operates smoothly. ⑷ Large capacity, high speed, high separation efficiency, high production capacity, high degree of automation, low noise, and low labor intensity. Working principle When the drum rotates at high speed, it will generate centrifugal force that is thousands of times greater than its own weight, causing the sugar paste on the wall to be subjected to centrifugal force. The sugar grains are trapped in the drum by the sieve, forming a filter layer. Under the action of centrifugal force, molasses needs to pass through the filter layer and sieve, and then flow out from the drum hole wall to complete the separation of crystals and mother liquor. A sugar paste separation can be divided into four stages, namely the formation stage of the loading filter layer, the centrifugal honey removal stage, the honey washing stage, and the drying stage.

|