PRODUCT CENTER

|

|

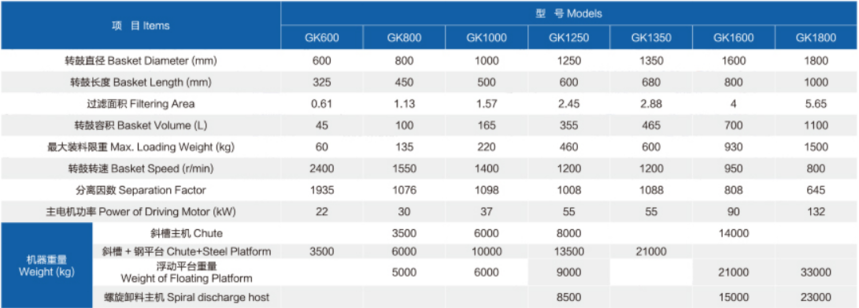

GK horizontal scraper fully automatic discharge centrifuge

收藏

DESCRIPTION The GK type horizontal centrifuge is a fully automatic filtration centrifuge that operates continuously, intermittently, with a wide scraper and high-speed scraping. It can complete processes such as feeding, separation, washing, dehydration, unloading, and blowback at full speed. Commonly used for washing and solid-liquid phase separation of suspension media containing solid particles. This product has a high separation factor, short single cycle time, large processing capacity, and can obtain relatively dry filter residue and good washing effect. Product Configuration Project Configuration The control method includes PLC control, touch screen human-machine interface, and supporting electrical hydraulic actuators, which can achieve fully automatic remote control. Safety protection includes speed detection, over vibration protection, cover opening protection, overload protection, overheating protection, scraper action protection, nitrogen protection, electromechanical interlocking, etc. The discharge method is open chute discharge or integrated discharge with spiral conveyor scraper. Variable frequency braking, energy consumption braking or energy feedback braking can achieve stepless speed regulation, energy-saving and environmentally friendly, and more reliable operation. Choose to configure online cleaning system, nitrogen protection system, steel platform, hydraulic locking device, etc. Other customer requirements. The door cover and machine base are designed with a dovetail groove structure to match the flange, ensuring reliable sealing. Fully hydraulic locking door cover, dual locking protection, reliable structure, easy operation. Fully enclosed explosion-proof structure design, meeting GMP standards in the pharmaceutical industry and flammable and explosive locations. Configure material layer controller to effectively control material thickness, prevent overload operation, and prevent material leakage. Hydraulic drive ensures smooth unloading. Detachable hard alloy blade, wear-resistant, long service life. Spiral discharge, high filter cake collection rate, effectively preventing material blockage. Supported by front and rear rolling bearings, it has high rigidity and low rotational resistance. The scraper bracket is welded and polished as a whole, with high structural strength, good rigidity, and smooth material scraping. The service life can reach 30 years. High load-bearing capacity and good vibration reduction effect. The machine base is designed with an integrated structure, which is fully processed, safe, and aesthetically pleasing. The front and rear bearing supports are processed coaxially, with high coaxial accuracy. The main shaft sealing sleeve adopts ion coating technology, which is wear-resistant, corrosion-resistant, and has a long service life. Whole welding, stress relief, high strength, and good seismic resistance. Adopting multiple sealing structures such as lip seal, airtight seal, and labyrinth seal; The transmission seal is reliable. The transmission adopts a forced oil injection lubrication method, which has good lubrication and cooling effects. The spindle components are equipped with temperature, speed, vibration and other detection devices, which can monitor the operation of the equipment in real time.

|