PRODUCT CENTER

|

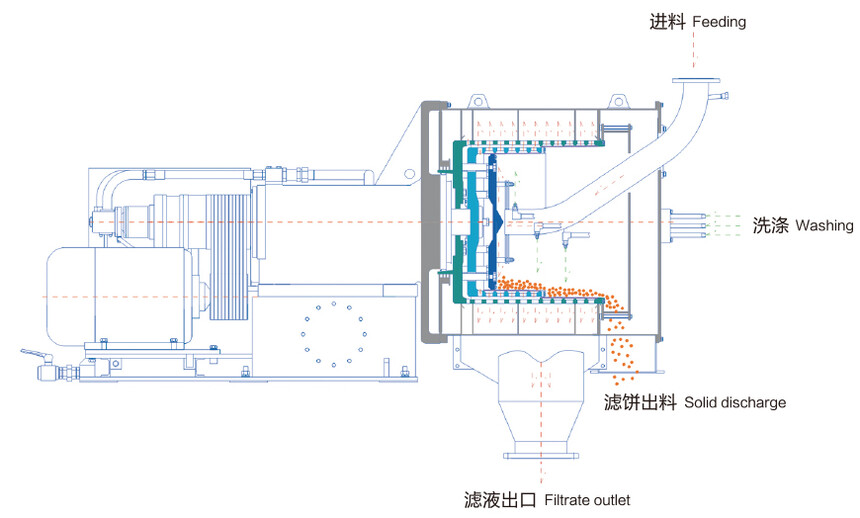

HR piston pushing centrifuge

收藏

DESCRIPTION The HR series piston push centrifuge is a filtration centrifuge with continuous feeding and intermittent discharge. It is mainly composed of hydraulic system, feeding mechanism, machine base, casing, transmission, drum, and other parts, and can achieve continuous feeding, separation, washing, unloading and other processes at full speed operation. Working principle The main motor drives the transmission device to run at full speed, and the material is introduced into the inner drum through the feed pipe. Under the action of centrifugal force, it is evenly distributed on the filter screen wall of the inner drum. The liquid phase material flows into the discharge pipe through the filter screen and the drum wall hole, while the solid phase material is intercepted by the filter screen and forms a filter cake layer inside the inner drum. The inner and outer drums rotate at the same speed. Under the push of the piston, the inner drum continuously moves back and forth in the axial direction. Under the push of the feeding disc, the material is discharged from the inner drum into the outer drum for further separation and formation of an annular filter cake layer. Under the reciprocating push of the outer end face of the inner drum, it is intermittently discharged from the outer drum and discharged outside the machine through the scraper groove. High separation factor, material can be dehydrated and washed at multiple levels, with good washing effect and low moisture content. Continuous operation, large processing capacity, high efficiency, and smooth operation. The mother liquor has a low solid content and can be discharged by mixing or splitting with the washing solution. Low and uniform energy consumption.

|