PRODUCT CENTER

|

|

SB three legged closed manual loading and unloading centrifuge

收藏

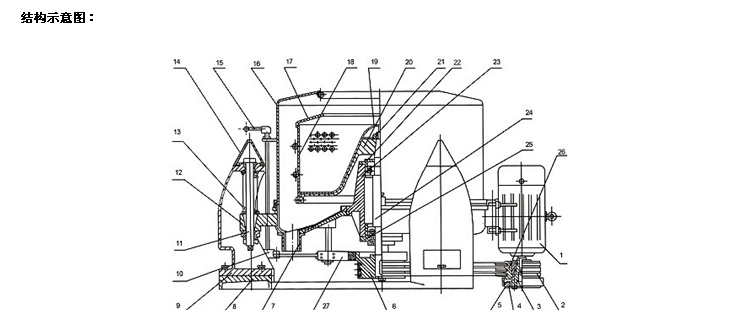

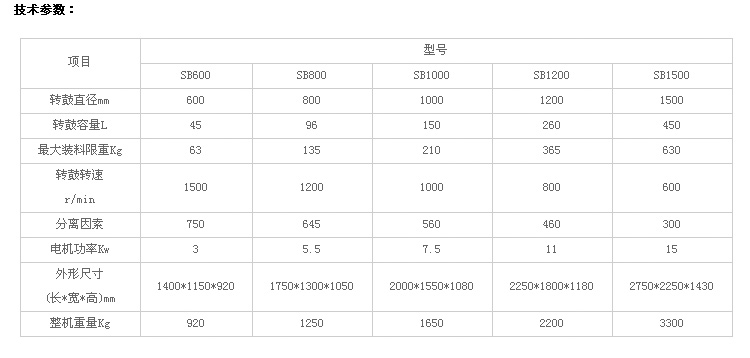

Main features: 1. Three legged manual loading and unloading centrifuge: The overall structural design is reasonable, the transition of structural components is smooth, the surface is polished, and the external structural components, fasteners, and drum can all be made of customer selected materials (stainless steel, titanium, carbon steel, rubber lining, plastic lining, PTFE lining, etc.). 2. The shell of the SB centrifuge is a large flip cover structure (with a cover configuration of feeding tube, washing tube, observation mirror, and lighting hole). The body design adopts a closed structure, and the sealing components are made of silicone rubber or fluororubber. It can meet the requirements of airtight explosion-proof and is suitable for applications in toxic, flammable, and explosive environments. 3. Drive mode: ordinary asynchronous motor, explosion-proof asynchronous motor or variable frequency explosion-proof. There are two types of motor installation: B3 and B5. 4. The three legged manual loading and unloading centrifuge has strong versatility and a wide range of applications. It is suitable for separating suspensions containing solid particles ≥ 0.01 mm. Solid particles can be in granular, crystalline, or fibrous forms, and can also be used for dehydration of finished products such as yarn bundles and textiles. 5. The centrifuge brake device can be used in three braking modes: holding brake, expansion brake, and frequency converter brake. There are two types of foundations: those with foundations and those without pouring foundations (equipped with shock absorbers) 6. There are several concerns about using variable frequency starting for centrifuges, including: (1) adjustable separation factor; Non contact energy consumption braking system; (2) Anti static belt drive. 7. A sealed centrifuge can be equipped with a nitrogen protection system to ensure that the centrifuge chamber is isolated from the external air.

|